Summary

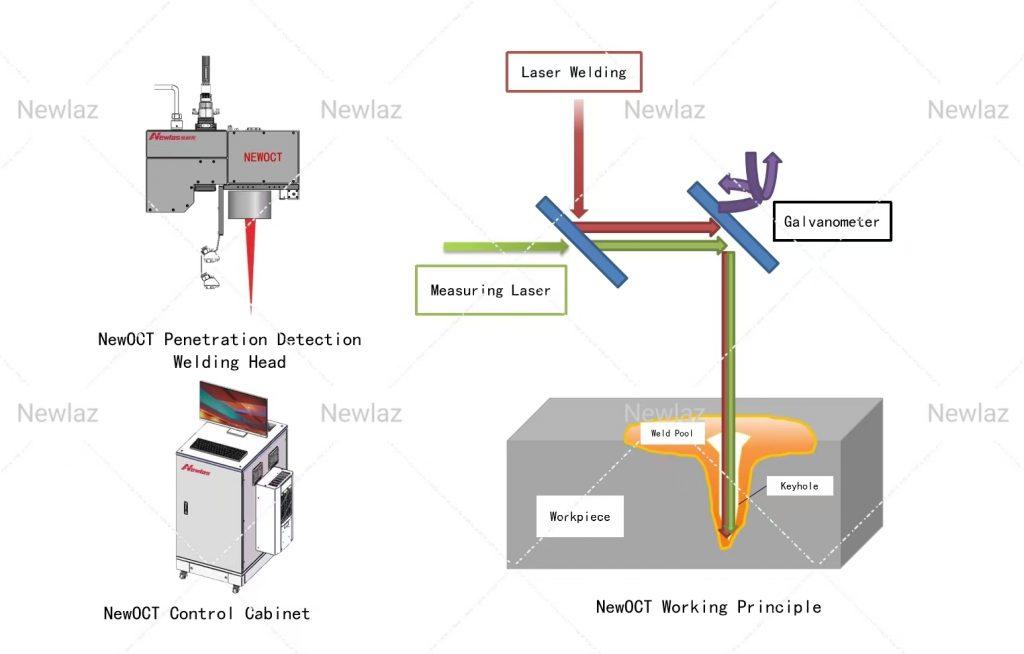

NewOCT Laser Penetration Detection Subsystem uses optical coherence tomography (OCT) to rapidly scan the workpiece at the welding locations. Through artificial intelligence algorithms, 3D scanning imaging is achieved, enabling real-time micron-level measurement of the weld penetration inside the keyhole during the welding process. This article presents NewOCT Laser Penetration Detection Subsystem on the structural composition, functional characteristics, and applications in the manufacturing of new energy vehicles.

Ⅰ Structural Composition

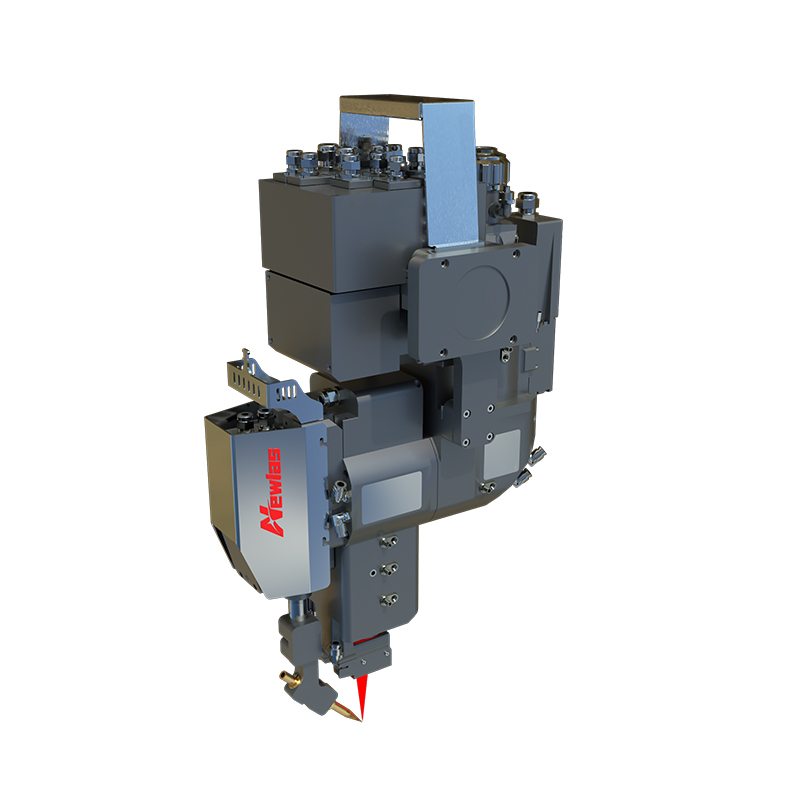

According to coupling the measuring laser and the welding laser coaxially, the depth of the keyhole in the molten pool can be directly measured during laser welding, enabling real-time monitoring of the laser welding penetration depth. The OCT scanning beam scans the surface of the workpiece at a high rate. Each depth generated is recorded in the database, including the generation time of the penetration depth and various key parameters, which is convenient for traceability and offline analysis. The equipment can be equipped with various types of welding heads: fixed-focus heads, wobble heads, galvanometer heads, etc. When paired with a galvanometer, the penetration depth measurement can be performed for any material and any Wobble oscillation type, which is suitable for various welding application scenarioses, achieving high-speed welding and ensuring welding quality.

II. Functional Characteristics

- The detectable penetration depth can reach 12mm, with a detection accuracy of ±0.1mm;

- It is compatible with various fiber lasers such as single-mode and multi-mode;

- It can be matched with galvanometer welding heads, oscillating welding heads, and fixed-focus welding heads;

- It can realize 100% non-destructive full inspection of products;

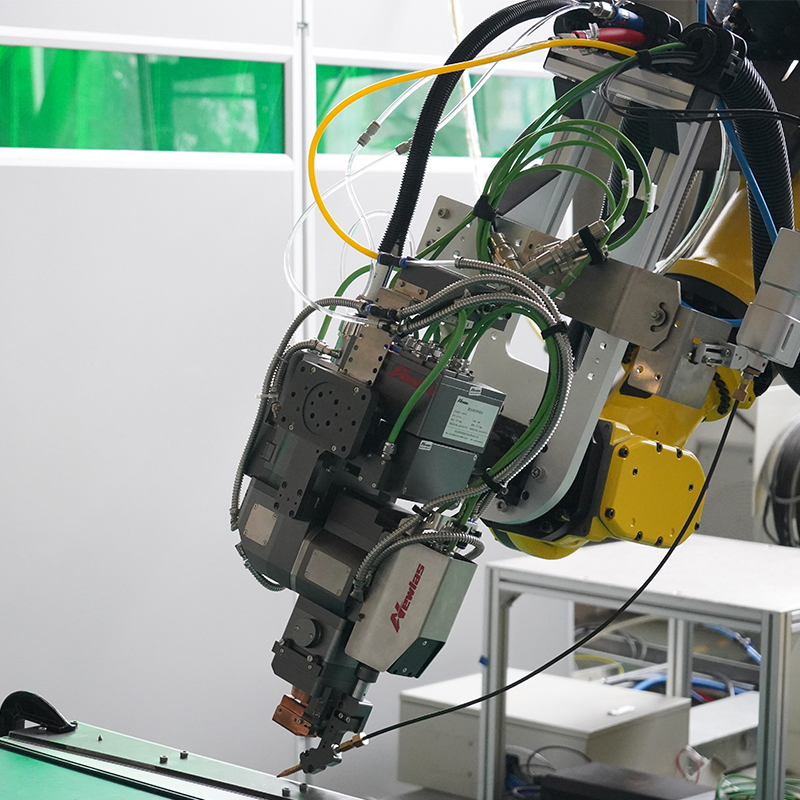

- It can be used in scenarioses such as robot welding and three-axis system welding.

III. Application Scenarioses

The NewOCT laser penetration depth detection subsystem uses the high-precision laser ranging principle to measure the penetration depth of the molten pool of various welding materials such as steel, aluminum, and carbon steel online and in real time. This system can be widely used for the welding penetration depth detection of the body-in-white, power batteries, and motor electronic control in the new energy vehicle industry. Body-in-white: Welding penetration depth detection of vehicle doors Power battery: Welding penetration depth detection of aluminum alloy, Busbar, and nickel sheets Motor electronic control: Welding penetration depth detection of red copper and IGBT modules

Conclusion

With the rapid development of the new energy vehicle industry, the industry shows a significant trend of electrification and intelligentization. The application prospect of laser intelligent manufacturing is very broad. As a technology-leading provider of laser welding solutions, Newlaz is dedicated to technological innovation and industrial application of laser welding core devices and subsystems in the vertical field of intelligent manufacturing, and is committed to providing users with one-stop laser application solutions aiming at intelligence and digitalization to meet the welding needs of different scenarioses.