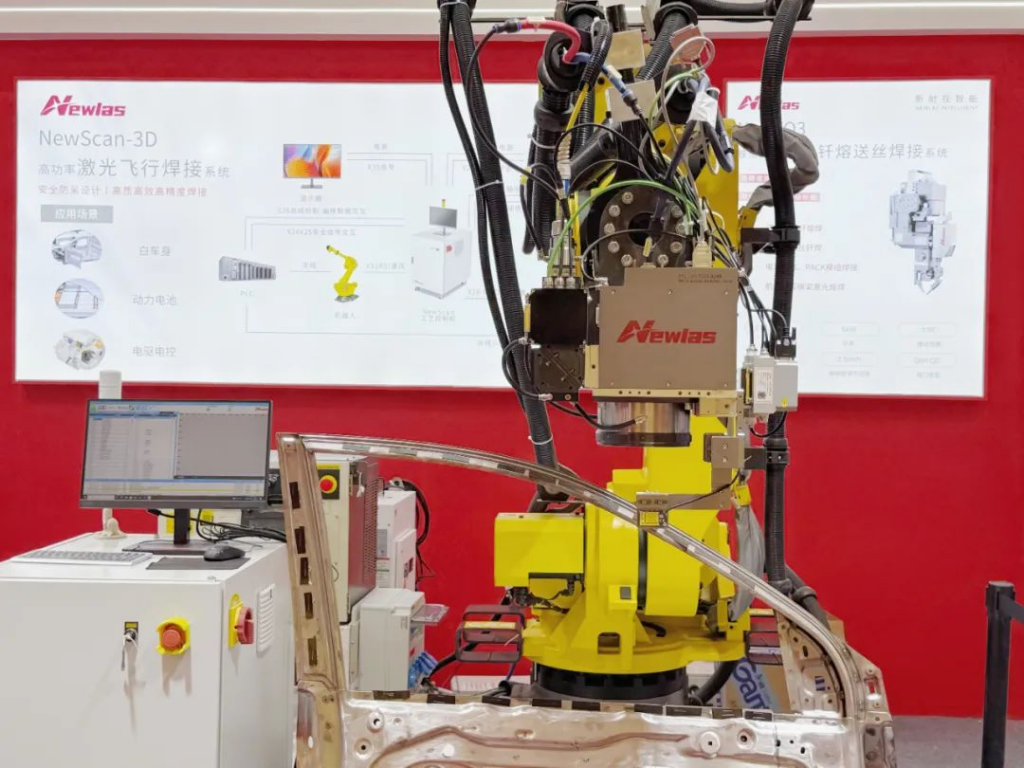

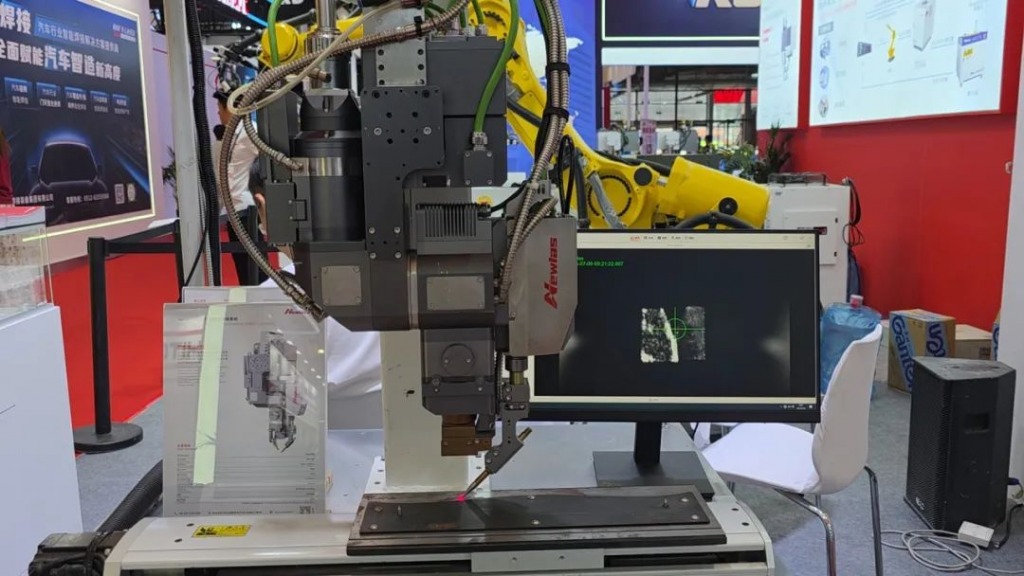

Amid the flashes of laser light, the art and technology of welding intertwine on the metal surface. There is no traditional scene of sparks flying, only nearly silent and precise operations — this is exactly the NewScan-3D Galvo Flying Welding System demonstrating the “non-contact” flying welding technology.

On the opening day of the 20th Shanghai AMTS International Automotive Technology, Equipment & Materials Exhibition, NewNex is presenting three innovative solutions to stand the test of global automotive manufacturing experts.

01 NewNex’s Three Innovative Solutions to Address Automotive Manufacturing Pain Points

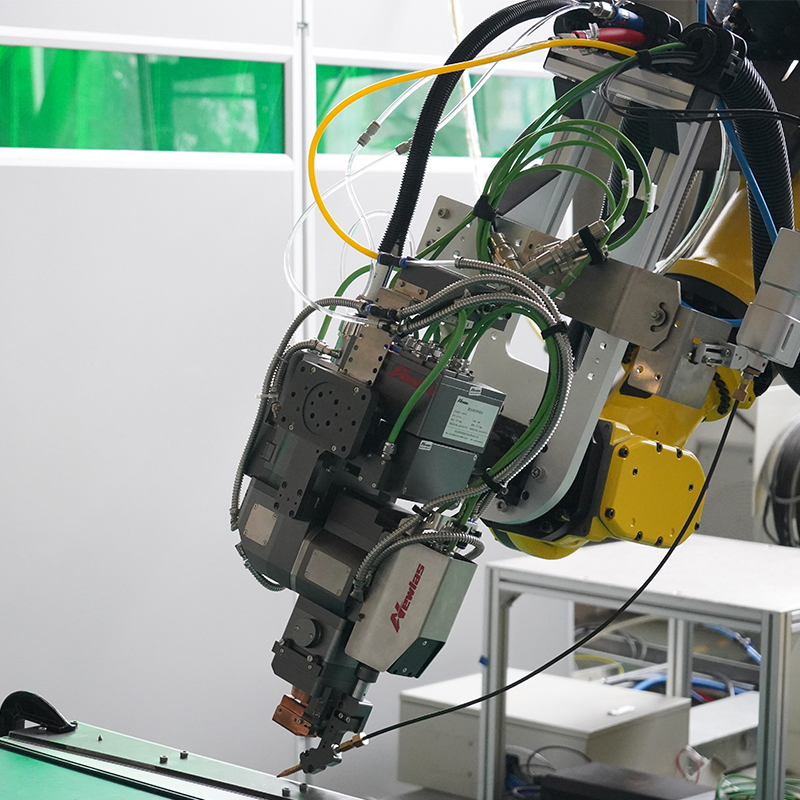

> NewScan-3D Galvo Flying Welding System

Designed specifically for the new energy vehicle (NEV) industry, it is equipped with multi-sensor detection and error-proofing technology, enabling high-quality welding during ultra-high-speed operation. The system has been successfully applied to the welding of key components such as power battery explosion-proof valves, pole posts, and sealing nails, with a welding speed that is over 40% faster than traditional methods.

> NewOCT Laser Welding Penetration Detection System

Based on the principle of high-precision laser ranging, it realizes full-process visual monitoring of the welding process. The system can perform real-time measurement of molten pool depth for various materials such as copper, aluminum, and carbon steel. It conducts closed-loop adjustment of the focal position before welding, acquires penetration data during welding, and automatically generates yield reports after welding.

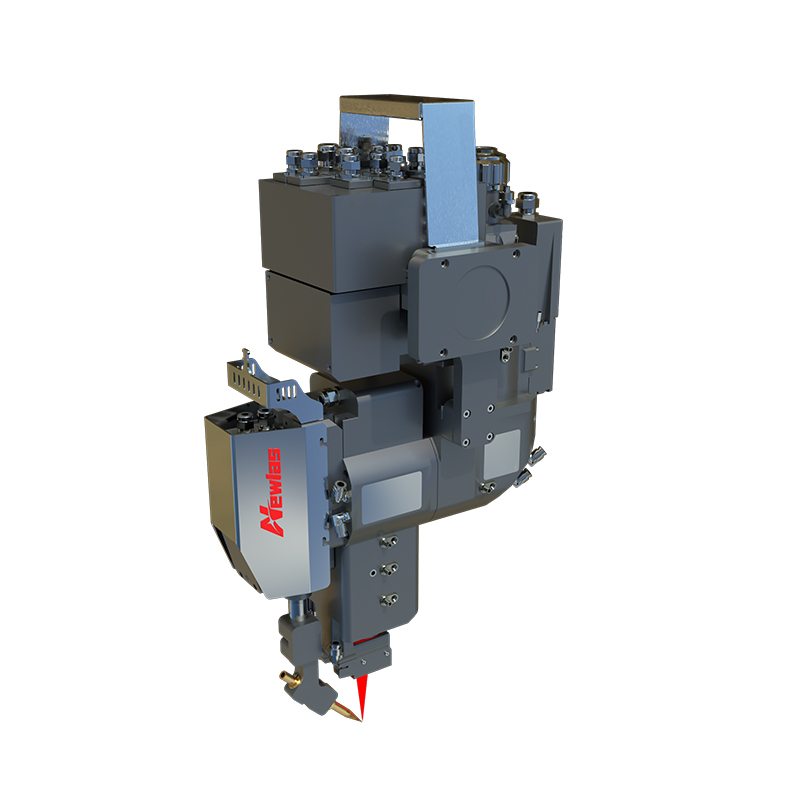

> NewFO3 Laser Wire-Feed Brazing Welding System

It features high-precision weld seam tracking and automatic focal length compensation functions. The wire tactile sensor can precisely control the tracking force and automatically compensate for part deviations, demonstrating excellent adaptability in vehicle body manufacturing and battery tray welding.

02 Technical Speech: Laser Spiral Welding Solves Chassis Manufacturing Challenges

At 10:30 a.m. on the opening day of the exhibition, Liu Gang, Newlas’s Solution Director & Process Expert, delivered a keynote speech titled”Laser Spiral Welding Promotes Quality Improvement, Cost Reduction, and Efficiency Enhancement in Integrated NEV Chassis Manufacturing”at the Technical Forum Area of Hall W4. The speech directly addressed the core pain points in current NEV chassis manufacturing: traditional laser spot welding can hardly meet the high-strength connection requirements of integrated die-cast chassis, and is also inefficient and costly.

Director Liu analyzed on-site how laser spiral welding technology solves this problem:

Its welding speed is 4 times that of ordinary spot welding (0.8 seconds per spot), significantly improving production line efficiency; – Through high energy density, a denser weld nugget is formed, increasing the spot strength by more than 30%; – Its energy utilization rate is 8 times that of conventional spot welding, greatly reducing energy consumption and practicing green manufacturing; – Precise welding can be achieved wherever the laser beam can reach. In NEV steel chassis and integrated vehicle bodies, this technology can streamline the number of workstations, reduce robot deployment, and directly replace traditional spot welding to achieve efficient and reliable connection between panels and frames, providing a solution for smart manufacturing.

Laser is no longer just a fleeting spark on the production line, but a precise brushstroke of smart manufacturing, writing a chapter of China’s intelligent innovation on the metal surface. There are two days left for the Shanghai AMTS Exhibition. More answers about the future of welding technology are gradually unfolding at the Shanghai New International Expo Center. NewNex looks forward to your visit at Booth W2-B05.